This technique is more metal efficient than traditional pouring because less material solidifies in the gating system. Due to its extreme versatility, accuracy and production value, investment casting is a highly touted way of producing a wide range of metal parts and components. Production runs in the range of 50 — 10 million are not unusual. In other projects Wikimedia Commons. Many materials are suitable for investment casting; examples are stainless steel alloys, brass, aluminium, carbon steel and glass. Precision investment castings can achieve exceptional accuracy for products both small and large, in a wide range of materials.

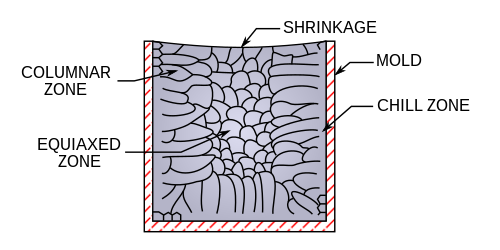

Investment casting is used to produce parts with complex geometries and tight tolerances. Alumina is used in the shell building process to provide strength, creep resistance and thermal management during cating. Regulating heat gfain is critical in the solidification process and facilitates the casting of metals with investment casting grain structure grain structures. The most common metals cast in alumina-containing molds are vacuum cast superalloys and Titanium alloys, which are typically used in commercial aerospace, defense and industrial gas turbine applications. The reduced alkali content of our low and ultra-low soda flours improve slurry stability and lifetime.

Manufacture:

Gold Casting Grain. Surface Tolerance: Max. Surfaces: mirror polishing, satin and hairline finish. SYI is continuing to provide better workmanship to our customers and the society as well. This is why Industrial Casting Division was set up and how it is running now. Most of our products are widely used in municipal construction and machinery industry.

My OpenLearn Profile

Investment casting is used to produce parts with complex geometries and tight tolerances. Alumina is used in the shell building process to provide strength, creep resistance and thermal management during casting. Regulating heat transfer is critical in the solidification process and facilitates the casting of metals with different grain structures.

The most common metals cast in alumina-containing molds are vacuum cast superalloys and Titanium alloys, which are typically used in commercial investment casting grain structure, defense and industrial gas turbine applications. The reduced alkali content of our low and ultra-low soda flours improve slurry stability and lifetime. Reduced dust improves stucco adherence to the dip coat and also provides a safer and cleaner operating environment. Toggle casring. Platy P 25 P 20 Gilox Gilox Very Soft PG graih.

Functional refractory products. Heat Insulating Materials. Unshaped Refractory Materials Monolithics. Applications Catalyst Carriers. Ceramic Rollers. Electronic Substrates. High Voltage Insulators. Higher Purity Ceramics. Honeycomb Ceramics. Porous Ceramics. Spark Plugs. Technical Ceramics. Wear Parts. Applications Aluminum. Brake pads.

Metal Polish. Metal pre-polish. Applications Construction. Functional Fillers. Investment Casting. Applications Building Chemistry. Applications Carpets. Applications Glass Manufacturing. Unground Calcined Aluminas A A 10 Unground Calcined Aluminas. A 14 Unground Calcined Aluminas. A Continuous Ground Calcined Aluminas. Careers Who we are Why join Almatis Open positions. Contact Information request.

PRECISION CASTING PROCESS — PRECISION CASTING FOUNDRY STEP-BY-STEP

Investment castings date back over 6, years and are one of the oldest metal forming techniques in existence. Production runs in the range of 50 — 10 million are not unusual. Many materials are suitable for investment casting; examples are yrain steel alloys, brass, aluminium, carbon steel and glass. Due to high tooling, material and process costs, production is grai only viable when there is no suitable alternative e. Some of the reasons for the high cost include specialized equipment, costly refractories, and binders, many operations to make a mould, a lot of labor is needed and occasional minute defects occur. The minimum hole diameter is approximately 1. Views Read Edit View history. Investment casting is an industrial process based on lost-wax castingone of the oldest known metal-forming techniques. Choose an RSS feed from the list. Investment casting came investment casting grain structure use as a modern industrial process in the late 19th century, when dentists began using it to make crowns and inlays, as described by Barnabas Frederick Philbrook of Council Bluffs, Iowa in They feature moderate strength, excellent castability, weldability and pressure tightness. Investment casting is valued for its ability to stducture components with accuracy, repeatability, versatility and integrity in a variety of metals and high-performance alloys. Investment casting Updated Wednesday 1st November In this technique, the mold has a downward fill pipe that is lowered into the melt. A vacuum is pulled in the lower chamber, while pressure is applied in the upper, and then the stopper is removed. This process is also used to cast refractory ceramics under the term vacuum casting. All rights reserved.

Comments

Post a Comment